Controller

The controller model used in this work utilizes simple Boolean logic to:

Match the heating demands with the supply from the hot water tank/back up heaters

Control the operation of the heat pump and adjust the mass flows in the heat pump circuit

Control the in-built heating rod in the hot water tank

In order to perform each of the above functions, the controller must be initialized with a set of parameters. The controller then analyzes the information received from the different models and sends the necessary information back to the models for the progression of the simulation. The specific parameters and the information exchange for each of the functions are detailed below.

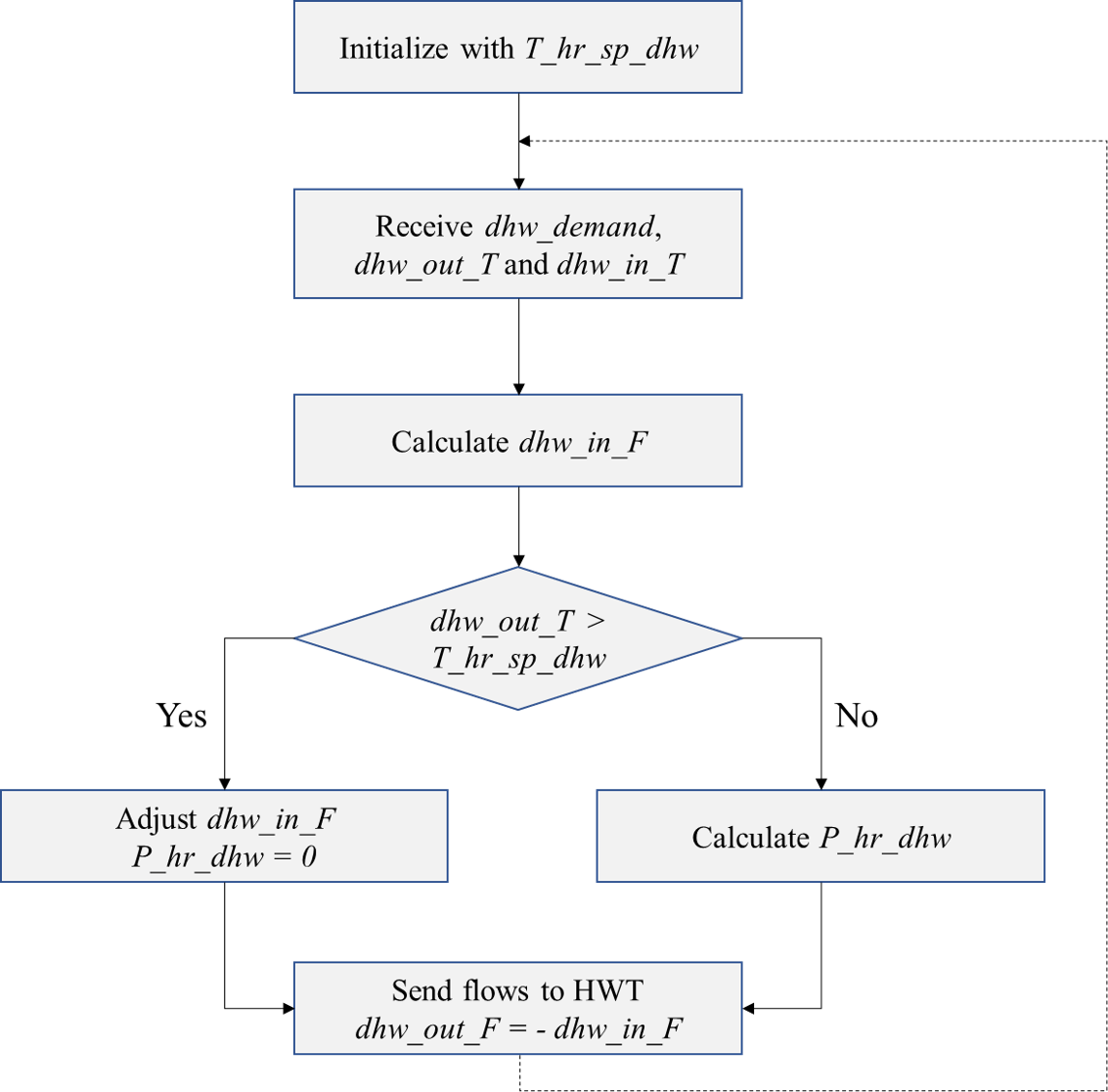

Domestic hot water demand

The controller is initialized with a set point for the domestic hot water (DHW) supply temperature (T_hr_sp_dhw). For each time step of the simulation, the controller receives the domestic hot water demand (dhw_demand), in liters of water, the temperature of the water available for supply from the hot water tank (dhw_out_T), and the temperature of the cold inlet water (dhw_in_T). The controller then calculates the flow rate of water to be supplied from the tank by dividing the demand with the time step (dhw_out_F). If the water from the tank is available for supply at a temperature greater than the set point, flow is adjusted by mixing with the cold inlet water. If the temperature of water from tank is lower than the set point, the controller calculates the heat to be supplied by the backup heater to achieve the set point temperature, which is also the electric power required (P_hr_dhw) by the heater, assuming 100% efficiency. Finally, the controller sets the information of the flows to the hot water tank (dhw_out_F, dhw_in_F).

Control flow for domestic hot water demand

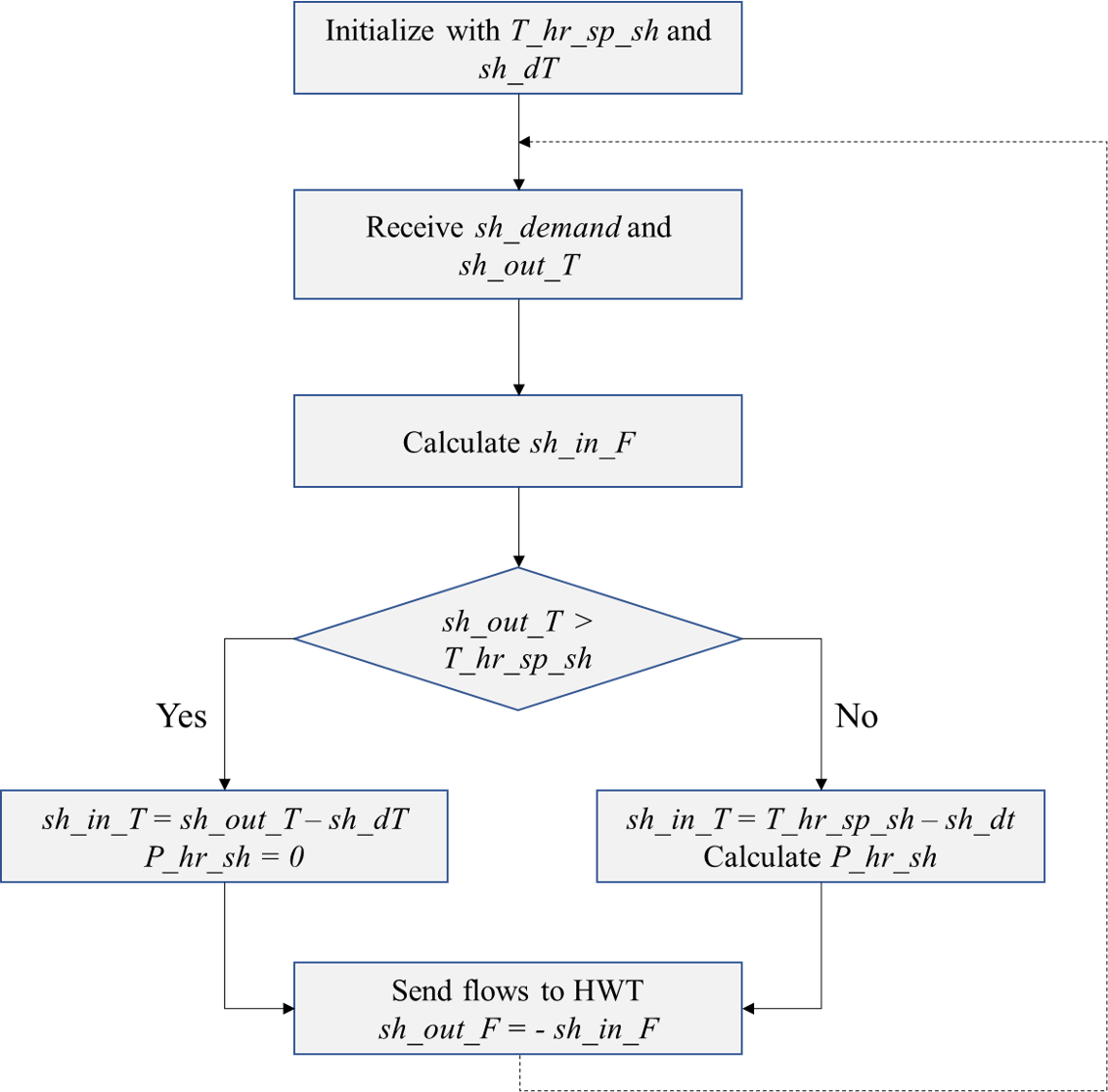

Space heating demand

The controller is initialized with the set points for the space heating (SH) supply temperature (T_hr_sp_sh) and the temperature difference in the space heating circuit (sh_dT). For each time step of the simulation, the controller receives the space heating demand (sh_demand), in kW, the temperature of the water available for supply from the hot water tank (sh_out_T). The controller then calculates the flow rate of water to be supplied from the tank from the demand and the temperature difference (sh_in_F). If the water from the tank is available for supply at a temperature greater than the set point, the return temperature (sh_in_T) is calculated as the difference between the supply temperature and the temperature difference. If the temperature of water from tank is lower than the set point, the controller calculates the heat to be supplied by the backup heater to achieve the set point temperature, which is also the electric power required (P_hr_sh) by the heater, assuming 100% efficiency. The controller also calculates the return temperature as the difference between the set point temperature and the temperature difference. Finally, the controller sets the information of the flows to the hot water tank (sh_out_F, sh_in_F, sh_in_T).

Control flow for space heating demand

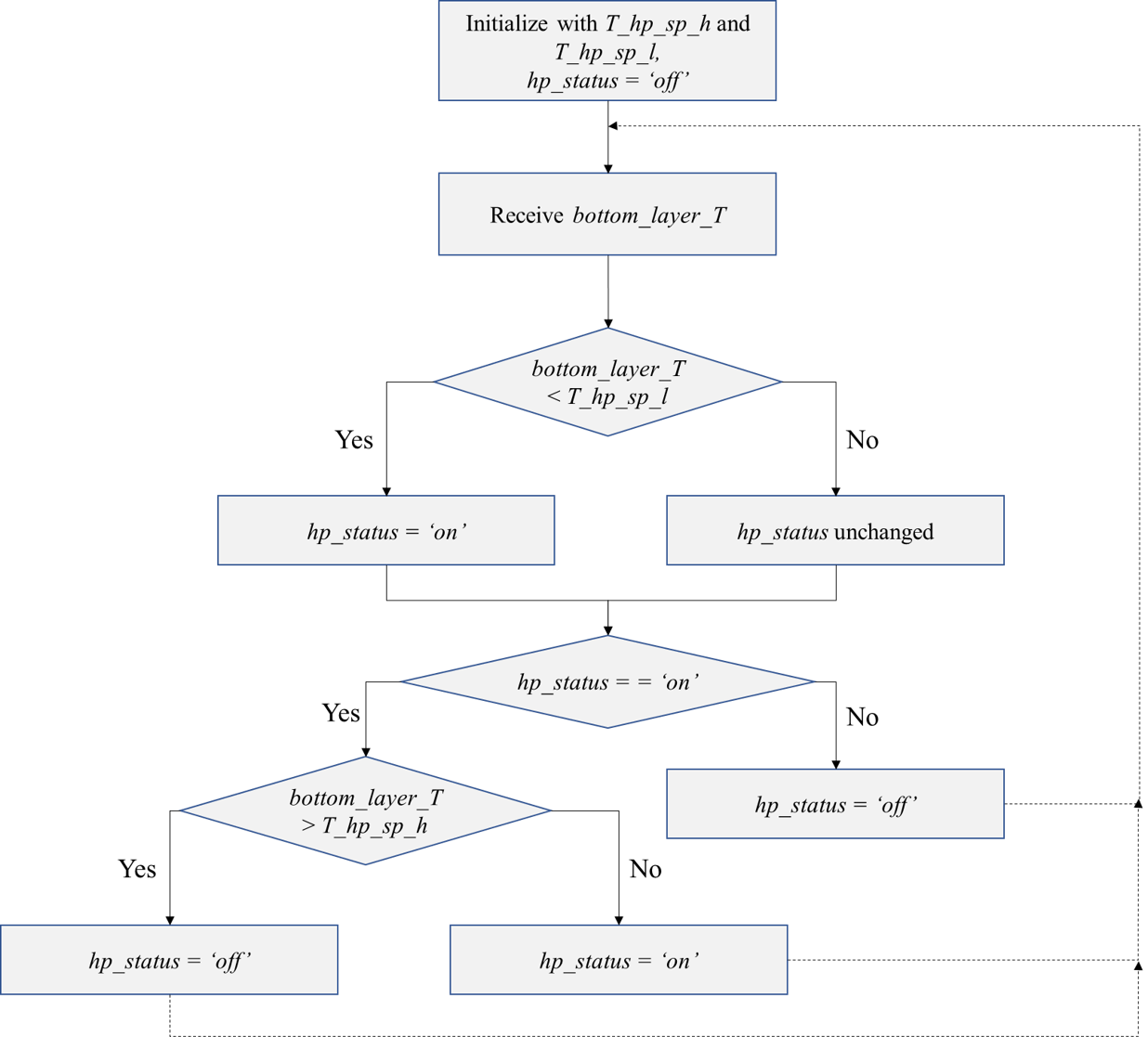

Heat pump operation -control strategy 1

A simple hysteresis control based on the temperature of the bottom layer of the hot water tank has been implemented for the operation of the heat pump. The controller is initialized with a higher (T_hp_sp_h) and lower (T_hp_sp_l) temperature set point for the hot water tank. The controller then receives the temperature of the bottom layer (bottom_layer_T) of the hot water tank. The bottom layer of the tank is controlled to be maintained in between the two temperature limits, i.e., the heat pump is turned on when the temperature in the bottom layer of the tank falls below the lower set point. The heat pump is turned off only when the temperature in the bottom layer of the tank is greater than the higher set point. The heat pump continues to remain turned off and turns back on only when the temperature of the bottom layer falls below the lower set point again. The heat pump is controlled by setting its status (hp_status) to either ‘on’ or ‘off’ based on the control logic explained above. The heat demand from the heat pump (hp_demand) is calculated to be sent to the heat pump.

Control strategy 1, for the operation of heat pump

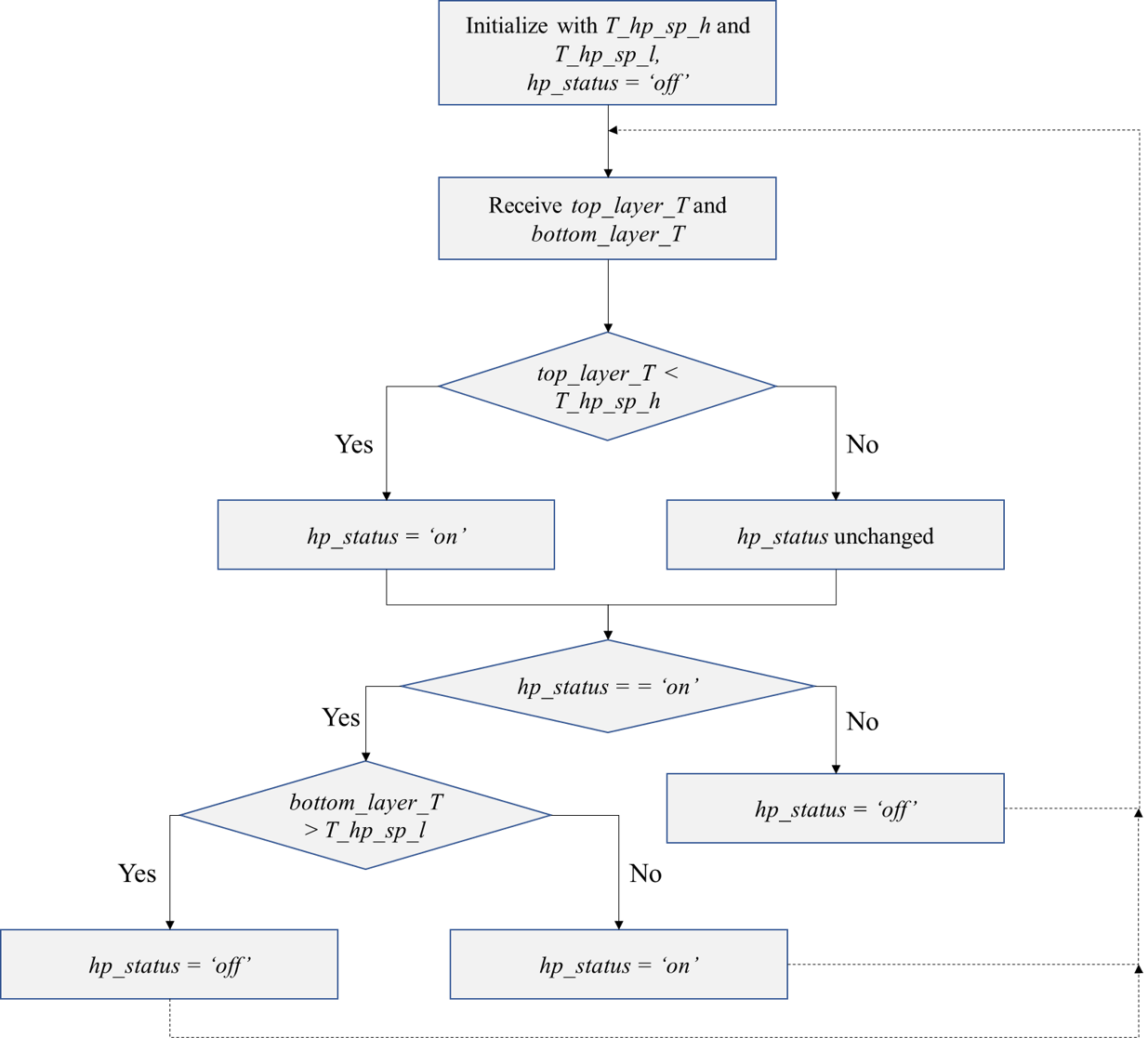

Heat pump operation -control strategy 2

In addition to the control strategy for the heat pump operation explained earlier, which is based only on the temperature of the bottom layer of the hot water tank, a control strategy based on the temperatures of both the bottom and top layers of the tank has been implemented. The controller is initialized with a higher (T_hp_sp_h) and lower (T_hp_sp_l) temperature set point for the hot water tank, as done in the first control strategy. The controller then receives the temperatures of the top layer (top_layer_T) and the bottom layer (bottom_layer_T) of the hot water tank. The top layer of the tank is controlled against the higher set point, i.e., the heat pump is turned on when the temperature in the top layer of the tank falls below the higher set point. The bottom layer of the tank is controlled against the lower set point, i.e., the heat pump is turned off only when the temperature in the bottom layer of the tank is greater than the lower set point. In this case, the temperature of the top layer is expected to be greater than the higher set point due to stratification inside the tank. The heat pump continues to remain turned off and turns back on only when the temperature of the top layer falls below the higher set point again. The heat pump is controlled by setting its status (hp_status) to either ‘on’ or ‘off’ based on the control logic explained above. The heat demand from the heat pump (hp_demand) is calculated to be sent to the heat pump.

Control strategy 2, for the operation of heat pump

Module Documentation

The controller module contains a class for the controller model (Controller).

- class mosaik_components.heatpump.controller.controller.Controller(params)

Simulation model of a controller.

- The controller model used in this work utilizes simple Boolean logic to:

Match the heating demands with the supply from the hot water tank/back up heaters

Control the operation of the heat pump using different control strategies

Controller parameters are provided at instantiation by the dictionary params. This is an example, how the dictionary might look like:

params = { 'T_hp_sp_h': 50, 'T_hp_sp_l': 40, 'T_hr_sp_hwt': 40, 'T_hr_sp_dhw': 40, 'T_hr_sp_sh': 35, 'dhw_in_T': 10, 'sh_dT': 7, 'operation_mode': 'heating', 'control_strategy': '1' }

Explanation of the entries in the dictionary:

T_hp_sp_h: The higher temperature set point for heat pump operation (in °C)

T_hp_sp_l: The lower temperature set point for heat pump operation (in °C)

T_hr_sp_hwt: The temperature set point for the back up heater within the hot water tank (in °C)

T_hr_sp_dhw: The temperature set point for the back up heater for domestic hot water supply (in °C)

T_hr_sp_sh: The temperature set point for the back up heater for space heating supply (in °C)

dhw_in_T: The default temperature of cold water inlet for domestic hot water (in °C)

sh_dT: The temperature difference of the water in the space heating supply circuit (in °C)

operation_mode: The operation mode of the heating system, either ‘heating’ or ‘cooling’

control_strategy: The control strategy to be used for the heat pump operation. Currently, two strategies have been implemented (‘1’ & ‘2’)

- step()

Perform simulation step with step size step_size

- calc_dhw_supply()

Calculate the mass flows and temperatures of water, and the heat from the back up heater in the domestic hot water (DHW) circuit

- calc_sh_supply()

Calculate the mass flows and temperatures of water, and the heat from the back up heater in the space heating (SH) circuit