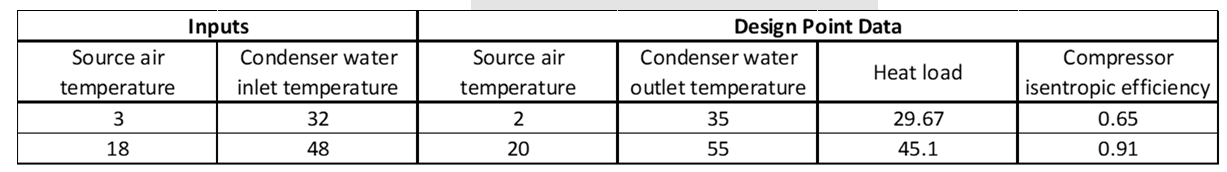

‘fast’ mode data

‘detailed’ calculation mode of the model for the simulations

After establishing the series of design points, the model is then developed to estimate the performance of the heat pump at any operating point within its range. The heat pump is used as the primary heating source for the hot water tank. The temperature of the water flow to the heat pump from the hot water tank, and the source air temperature are the required inputs.

The model checks if the conditions are within the operation range of the heat pump and ensures that the source air temperature is lower than the incoming water temperature. The source air temperature closest to the input value is then identified from the expanded heating capacity table. The model checks that the inlet water temperature is lower than the maximum possible condenser outlet temperature at the identified design source air temperature. Assuming a temperature difference of 5°C in the condenser in the design case, an initial condenser outlet temperature is estimated. The closest design point to the estimated condenser outlet temperature is then identified from the extended heating capacity table. In case this estimated condenser temperature is greater than the maximum possible outlet temperature, the maximum value is used as the design point. The heating capacity and the isentropic efficiency of the compressor corresponding to the design point source air and condenser outlet water temperatures are identified from the respective tables, the expanded heating capacity table and compressor efficiency table.

The model first performs a network calculation in the design mode at the identified design point operating conditions. An offdesign mode calculation of the network is then performed for the actual input operating conditions, based on the design mode calculation and the default characteristics of TESPy, to obtain the condenser outlet water temperature (supply temperature), the mass flow of water in the condenser and the power consumption of the heat pump.

Example of detailed calculation mode

‘fast’ calculation mode of the model

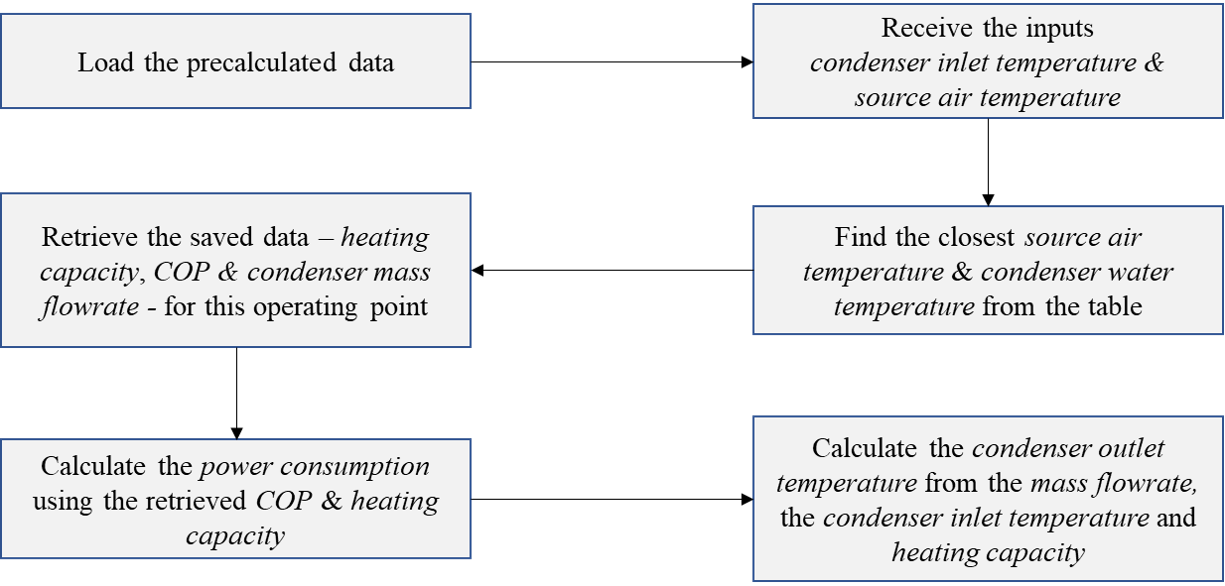

In addition to the detailed mode of calculation explained above, a fast calculation mode has also been implemented in the model to improve its computational speed. The model is discreetly parametrized over the entire operation range of the heat pump, at a resolution of 1°C for both the inputs, the source air temperature, and the condenser water inlet temperature. The detailed calculation mode can be implemented over this range of inputs and the output data from the model- the coefficient of performance (COP) of the heat pump and the condenser mass flow rate- can be saved. During the actual simulation, the saved inputs that are lower/closest to the actual input data are identified, and the saved output data for these points are used to calculate the outputs of the model, rather than performing the actual design and offdesign calculations. Though the granularity of the model is reduced, there is a significant improvement in the simulation duration.

Flowchart explaining the fast calculation mode of the TESPy heat pump model

Generation of ‘fast’ mode data

The data for the ‘fast’ calculation mode can be calculated and saved as follows:

Adding the new heat pump model

The initial parametrization of the new heat pump model, based on the nominal operating point, from the ‘Parametrization_NominalData.py’ file, should be added to the ‘_design_hp’ method of the heat_pump_design.py file (line 217).

‘fast’ calculation mode data generation

The tutorial in the ‘Fast_Calculation_Mode.ipynb’, should be followed to generate the fast mode data.

‘fast’ calculation mode data processing

The tutorial in the ‘Fast_Mode_DataProcessing.ipynb’ script should be used to process the fast mode data, to fill the missing values in the data that result from the errors in the model etc.

Module Documentation

- class mosaik_components.heatpump.Heat_Pump_Design.Heat_Pump_Design(params, COP_m_data=None)

Design of the heat pump model for the different calculation modes

- _take_closest(myList, myNumber)

Assumes myList is sorted. Returns closest value to myNumber. If two numbers are equally close, return the smallest number.

- _etas_heatload_id()

Used for all the calculation modes except ‘fixed’ mode.

Uses the pre-saved data from the “eta_s_data.json” file

Checks the inputs, cond_in_T and heat_source_T, against the limits of operation for the chosen heat pump model.

Identifies the closest design point for the inputs, for the ‘detailed’ calculation mode

- _design_hp()

Used in the ‘detailed’ calculation mode to solve the TESPy network of the heat pump in the design mode

Number of stages of compression can be 1 (default) or 2

Intercooler between the two stages of compression is optional

Superheater between the evaporator and the compressor is optional

fixed and variable mass flow in the evaporator

- p_cop_calc()

Calculates the power consumption and the COP of the heat pump in the ‘detailed’ calculation mode

- step(inputs)

Performs simulation step with the step size ‘step_size’

- step_error()

Sets the outputs of the heat pump model to 0